The Most Common Pickleball Paddle Construction Features: What They Are and Why They Matter

While most players focus on paddle weight, shape, and surface texture, what’s happening inside the paddle is just as important. Construction features determine how a paddle feels, performs, and holds up over time. Even if those details aren’t always visible from the outside.

In this blog, we break down the most common pickleball paddle construction features and how they affect power, control, comfort, and durability.

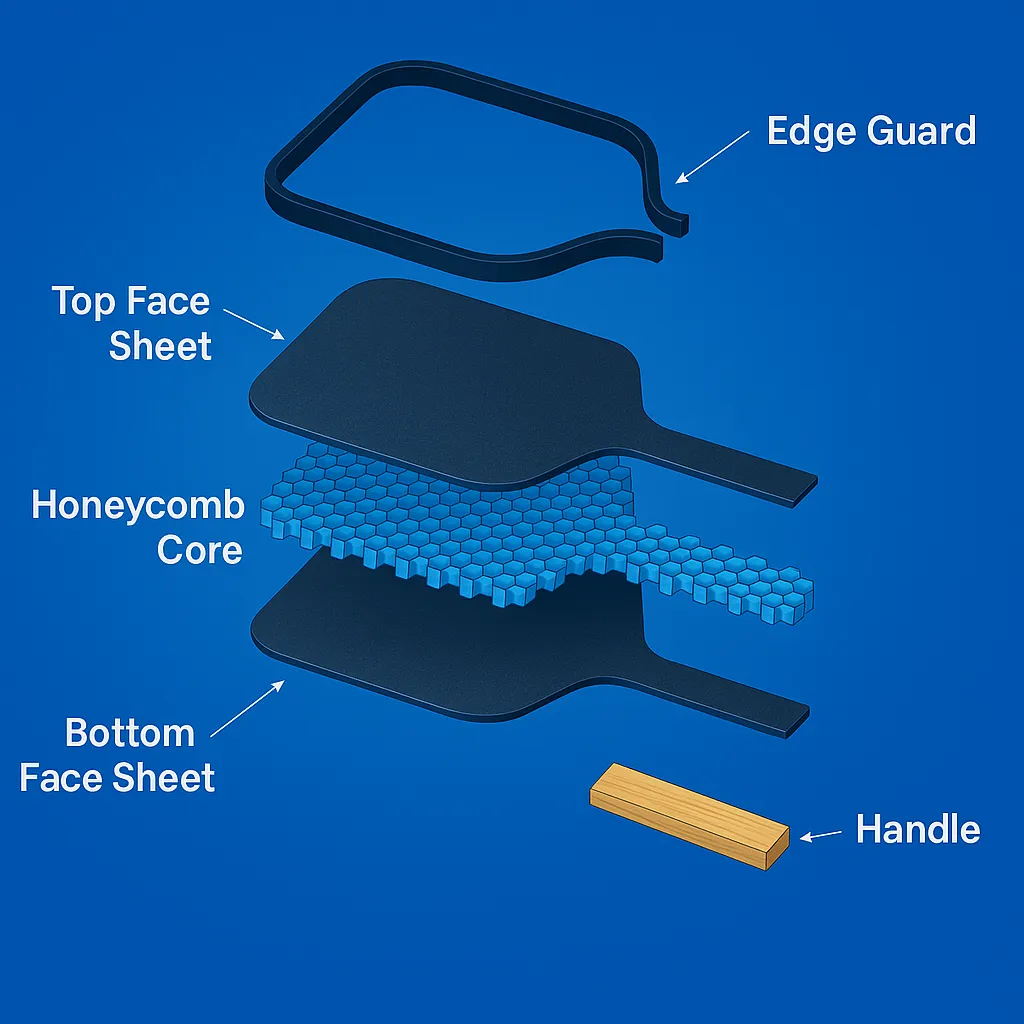

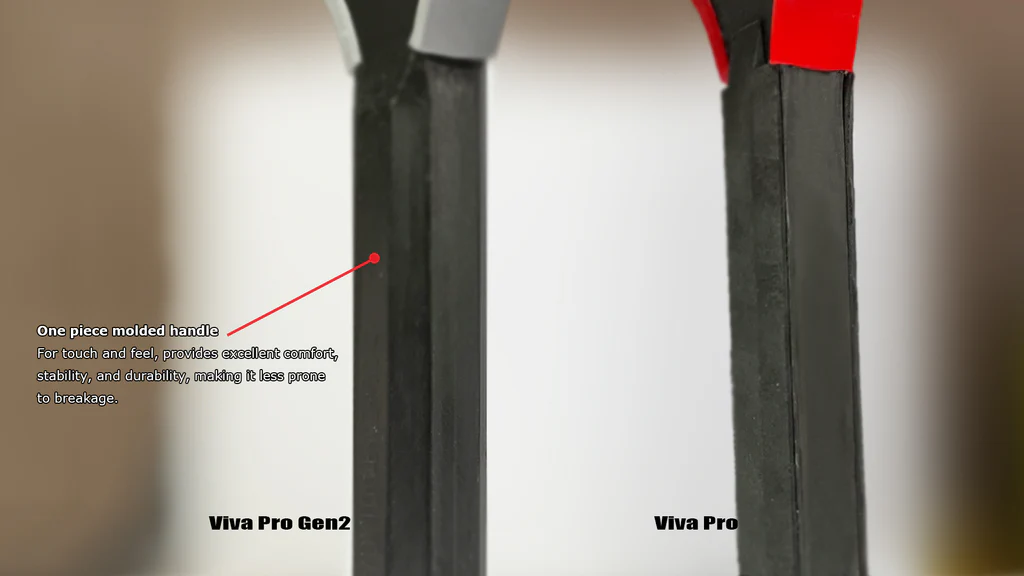

Comparing Paddle Frames: Bonded Body vs. Unibody

One of the most important construction differences lies in how the paddle handle connects to the face. This affects durability, power transfer, and feel.

Bonded Body Construction

Bonded Body refers to the traditional paddle construction method, where the handle is manufactured separately and glued onto the face.

Why it matters:

- Allows for lower production costs

- Can feel less solid or consistent during hard play

- More prone to looseness or breakage at the handle joint over time

Best For: Recreational players or those on a budget with the understanding that durability is limited compared to unibody designs.

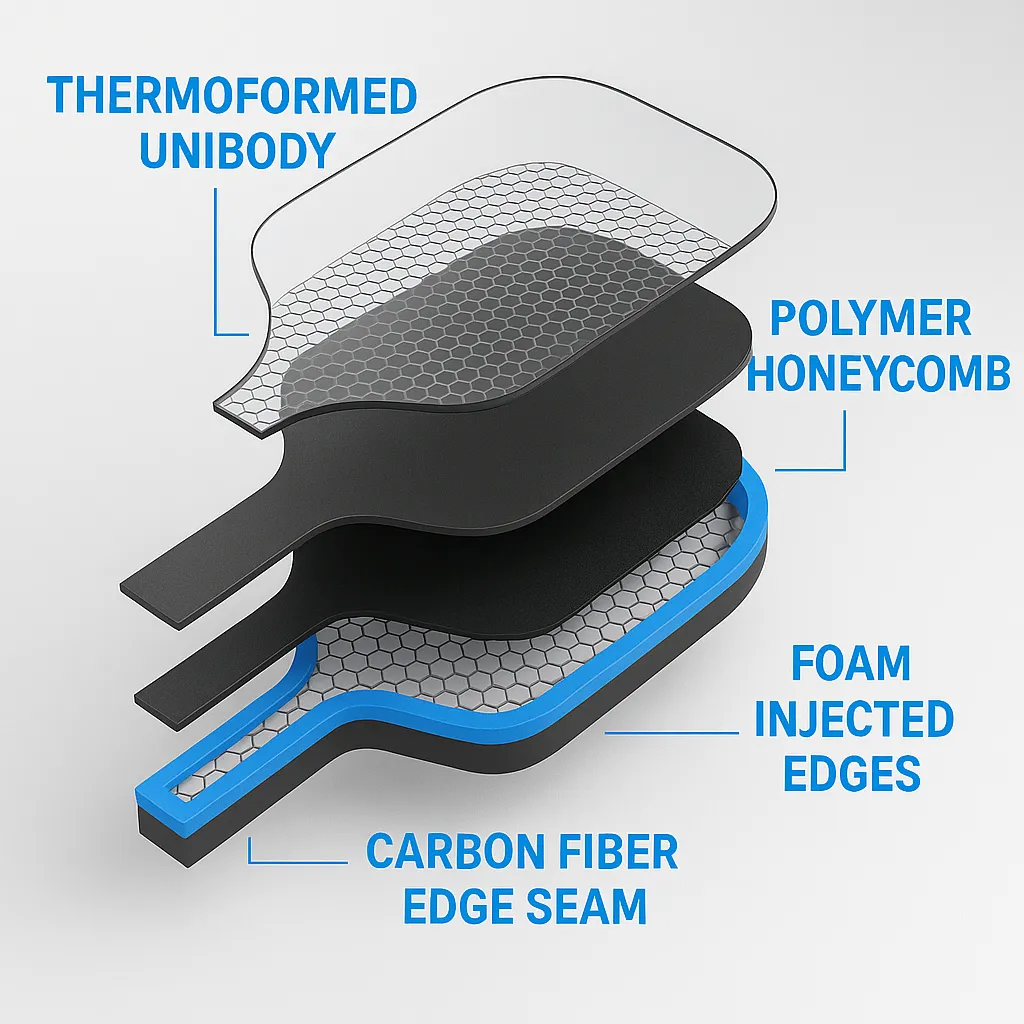

Unibody Construction

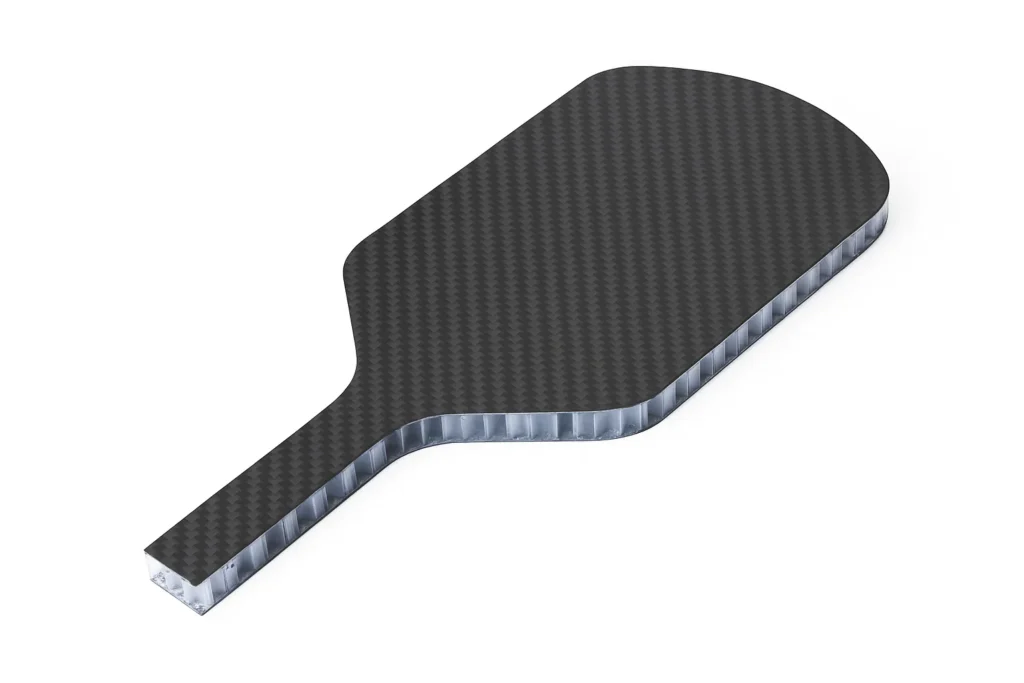

Unibody construction means the paddle face material (often carbon fiber) extends through the handle in one continuous piece. This can also occur when the face and handle are fused through a thermoforming process seen in gen 2 paddles and later. These thermoformed unibody paddles are extremely strong and durable.

Why it matters:

- Eliminates weak points at the neck of the paddle

- Provides a more solid, consistent feel across the entire frame

- Increases power transfer from the handle to the ball

Best For: Players who want a connected feel and long-lasting construction.

Other Key Construction Features

Foam Injected Edges

Foam-injected edges place soft foam around the perimeter of the paddle core. This construction style only started appearing in gen 1.5 paddles and above.

Why it matters:

- Expands the sweet spot

- Reduces vibration on off-center hits

- Improves control and comfort

Best For: Players who want a more forgiving, vibration-free feel.

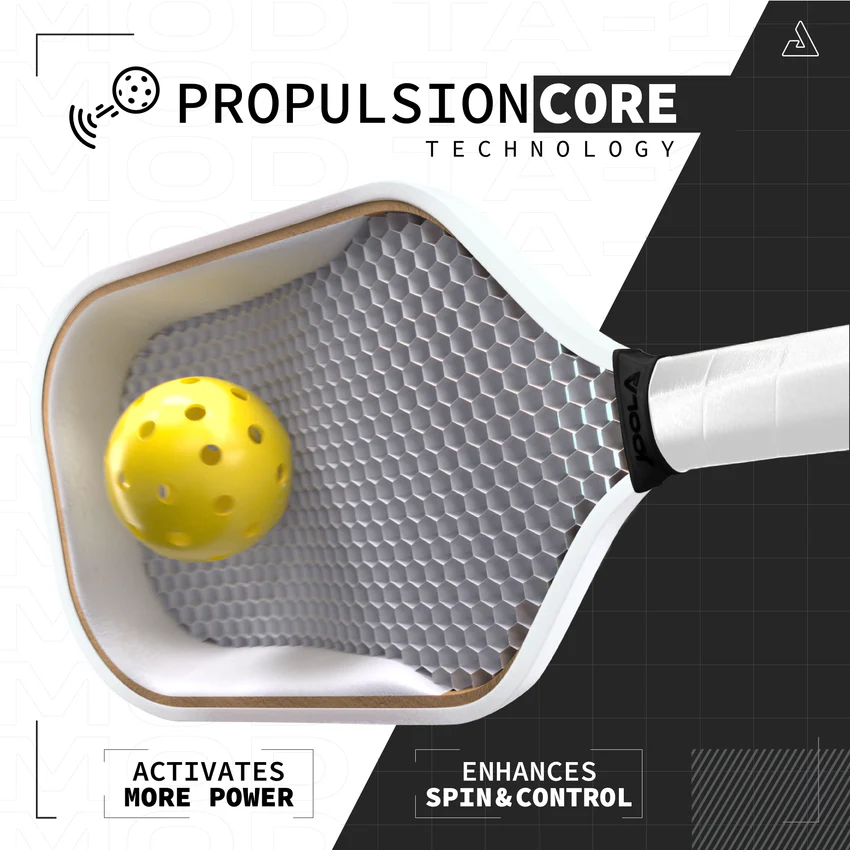

Floating Core

A floating core is suspended inside the paddle, often surrounded by foam for isolation. This construction style made its first appearance in gen 3 paddles.

Why it matters:

- Increases dwell time (the ball stays on the face longer) which can improve ball shaping on certain shots

- Creates a trampoline effect that launches the ball on drives

- May require a short break-in period for peak performance

Best For: Players who value power and ball shaping ability.

Solid Foam Core

A solid foam core replaces the traditional honeycomb core with a foam core, offering more consistency and durability. Different manufacturers will experiment with different densities and patterns of foam within a paddle. Foam cores are a key feature in gen 4 paddles.

Why it matters:

- Creates a smooth, consistent response

- Softens vibration and provides a unique feel

- Less common but growing in use for premium paddles

- No core crushing

Best For: Players seeking a more reliable and durable paddle.

Foam Injected Core

Foam is injected around the paddle’s internal core not just at the edges. Different paddle manufacturers will experiment with the foam’s placement. Foam injected cores made their first appearance in gen 3 paddles.

Why it matters:

- Adds power through a trampoline effect

- Expands the sweet spot

- Provides better ball acceleration on drives and counters

Best For: Players who want a blend of explosive power and control.

Forged Handle

A forged handle refers to a handle that is thermoformed separately from the paddle face, often using a solid, molded material that is then fused to the paddle body through a secondary thermoforming process or glue.

Why it matters:

- Allows manufacturers to precisely mold the handle into an ergonomic shape for comfort and grip stability

- Creates a handle that feels more solid and seamless in the hand

Best For: Players who prioritize comfort, grip confidence, and durability in the handle.

Final Thoughts: The Build Inside the Paddle Makes All the Difference

From how the handle is attached to the face, to how the core is supported and shaped, paddle construction plays a huge role in how it feels and performs. While some features improve power and durability, others support touch and comfort. Understanding these construction methods helps you choose a paddle that not only plays well, but lasts longer, feels better, and performs the way you want.